IN THIS ISSUE

- It Happened To One Of Us

- Fatigue is a State of Impairment

- Spray Safe, Stay Safe

- Who is at Risk Working in Hot Temperatures?

- Balancing an Employee's Right to Privacy While Protecting Their Health & Safety Needs

- Do You Know What To Do If You Are Stuck Outside in Lightning?

- Runovers Continue to be a Leading Cause of Death on Canadian Farms

It Happened to One of Us

Most farmers are hesitant to talk openly about incidents that have happened on their farm. While understandable, it is also unfortunate, as so many of us can relate to their stories and learn from them.

Earlier this year, Jeff Melchior of the Alberta Farmer Express spoke to Karleen Clark about an incident that occurred on her operation last fall. Karleen is a co-owner of KCL Cattle Company and is also on AgSafe Alberta’s Board of Directors. Karleen not only talked about what happened and the damage that resulted, but also about the root cause of the incident: fatigue.

Damaged equipment is bad enough for any farmer in the middle of harvest, but a co-owner of a southern Alberta farm says they could have lost much more. KCL Cattle Company lost thousands of dollars last fall when an employee crashed into a header after a long day in the field. The header was totalled, as was the truck hauling it. The culprit? Fatigue.

“It had been a long stretch of harvest because we had had no weather delays, which is great, but I think you forget just how much weather delays help with fatigue,” said Karleen Clark, business manager with the Lethbridge-area operation. “We had just finished up a field; I think they finished around midnight. They decided to move the equipment to another field and start in the morning. There were two trucks pulling the headers. The one in the front slowed down to check a pivot. The one behind him had dozed off and so he ran into the one in front.”

Luckily, no one — including the driver who had fallen asleep — was hurt.

“Fortunately, we were able to get a header the next day but that was just a stroke of luck, I think. It could have been worse,” said Clark. “I know this feels like a small incident, but it was eye-opening to us as to how bad it could have been. If our employee had been hurt, that would really shake us because we’re all friends, we’re all family. It’s important to make sure everyone is staying safe.”

With another busy season approaching, KCL Cattle Co. is looking at ways to manage fatigue to prevent any similar (or worse) accidents. “We’ve had a lot of conversations about it. I think the biggest thing is to have honest discussions about fatigue,” said Clark, who serves on the board of directors of AgSafe Alberta. “There’s a sense of pride — farmers push to finish. I think it’s important to remind everyone that there are times when it’s not smart to keep going. “If you’re tired, don’t be afraid to say ‘hey I need to be switched out today. I need some help. I need to get some more rest. Or maybe let’s not move this equipment tonight. Let’s go rest first.’”

As a farm owner, Clark understands the need to seed and harvest quickly, “but a bad incident is going to cost you a lot more than a weather event or not getting your crop off in time.” Karleen Clark, co-owner of KCL Cattle Company, says she is re-evaluating safety on her operation after a fatigue incident last fall cost thousands of dollars but luckily no human injuries.

Excerpt reprinted with permission from the Alberta Farmer Express.

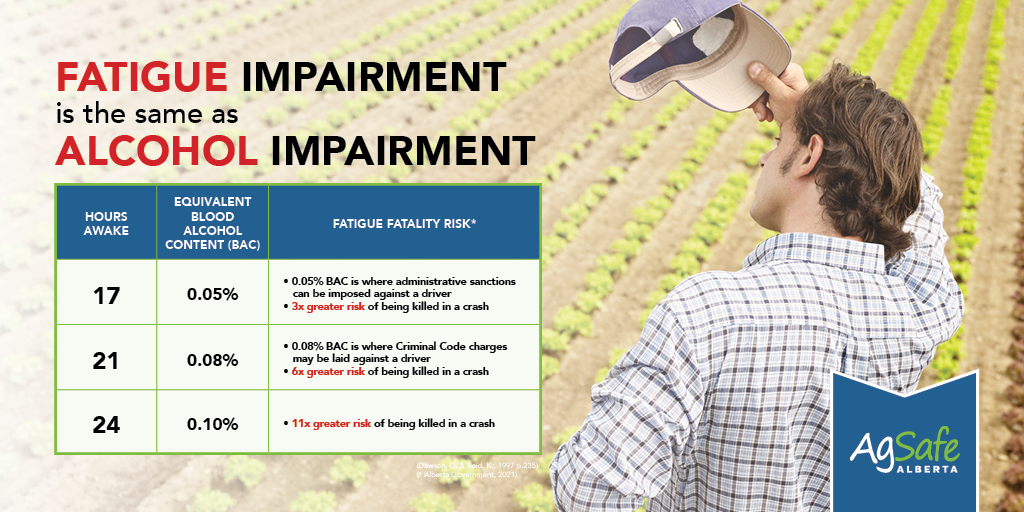

Fatigue is a State of Impairment

At this time of year, many of us are putting in some very long, hard work days while operating extremely large, noisy and potentially dangerous equipment. In other industries, this type of work would be considered safety sensitive – where an incident could result in serious injury to the person performing it or someone else.

We need to recognize that fatigue is a state of impairment. It reduces your alertness, your concentration and your reaction time, and is a common yet unrecognized hazard on farms and ranches. Like all hazards, once you recognize them, you can then assess them and do something to minimize the risk. Take a few moments to check out the links below and think about how your operation can better manage fatigue:

Fatigue, Extended Work Hours and Workplace Safety Bulletin by the Alberta Government

Find fatigue information and tools available from the National Safety Council

Spray Safe, Stay Safe

When was the last time you or the other people on your operation read a pesticide label and understood:

- What the hazards are?

- What the health risks are?

- What hazard controls, including but not limited to PPE, are needed?

- What symptoms of an exposure might look and what to do if an exposure occurs?

- What to do in case of a spill?

- What the safe re-entry period is, if one is known?

Whether someone is buying a pesticide, working directly with it (i.e., mixing it or applying it), or working near areas where it has been applied, there is key information that they need to be aware of. What this information is will depend on the product, it’s use, its application and other farm specific factors.

To support you and your farm team in understanding the hazards and risks of pesticides and other products, as well as how to better protect people and livestock from these hazards and risks, AgSafe Alberta has developed a WHMIS 2015, Pesticide, Veterinary Drug and Medicated Feed online course for farms and ranches.

Take this course for FREE until July 31st, 2023 using the promo code SPRAYSAFE23.

Who is at Risk Working in Hot Temperatures?

- People need at least 4 to 7 working days to get used to (acclimatize to) the hot temperatures, but it can take as long as 3 weeks for this to happen.

- Everyone is different; even some physically fit and healthy people may not fully acclimatize to the heat.

- Factors that may make it harder for someone to adapt to hot temperatures include:

- Being an older adult

- Infants and young children

- Having extra body weight

- Low fitness levels

- Poor general health

- Medical conditions that may increase someone’s risk of heat illness include:

- Heart disease

- Uncontrolled diabetes

- High blood pressure

- Respiratory disease

- Substances that may increase someone’s risk of heat illness include:

- Alcohol

- Cocaine

- Anaesthetics

- Morphine

- Cannabis

- Hypnotics; examples include benzodiazepines and barbiturates.

- Amphetamines; examples include Adderall®, Concerta®, Dexedrine®, Focalin®, Methylin®, Ritalin® and Vyvanse®.

- Anticholinergics; examples include diphenhydramine (Benadryl®), atropine and dicylomine.

- Psychotropic drugs; examples include aripiprazole, clozapine, risperidone and olanzapine.

Below are some helpful toolbox talks and other information to keep you and your farm team working safely this summer:

Who Is at Risk Working in Hot Temperatures?

Hydration and Heat Stress

Sun Safety Tips

Using the UV Index Scale

Health Canada’s Staying Healthy in the Heat Infographic

Balancing an Employee's Right to Privacy While Protecting Their Health & Safety Needs

Employees have the right to privacy and do not have to disclose what health conditions they have or what medications they may be taking. However, they should advise their employer of any reasonable restrictions or accommodations that might be needed in order for them to perform the work safely. In these situations, the employer may require the following information from a physician:

- If the injury or illness is permanent or temporary

- What restrictions and limitations the employee has

- Whether a treatment or medication the employee is taking will affect the employee’s ability to perform their duties.

For more information, review the Alberta Human Rights Commission’s interpretive bulletin Obtaining and responding to medical information in the workplace.

Do You Know What To Do If You Are Stuck Outside in Lightning?

If you find yourself outdoors and without a building, vehicle or tractor, there may be little that you can do to protect yourself from a lightning strike; this is why it is so important to go to a safe place at the first signs of an approaching thunderstorm. To reduce your risk of being struck by lightning in this situation, consider the following:

- Lightning is likely to strike the tallest objects in an area, make sure you are not one of them!

- Do not lie flat on the ground if outdoors in a storm.

- Avoid things such as isolated tall trees, hilltops, power poles, etc.

- Avoid open areas, such as a field.

- Avoid wire fencing, as lightning can travel long distances through it.

- Get away from bodies of water (water does not attract lightning but it does conduct electricity).

- Find dense areas of smaller trees surrounded by larger trees.

- Find low lying areas, such as a ditch or valley, but watch for flooding.

- Sheds and tents do not provide adequate protection from lightning.

SAFETY FIRST, LAST THOUGHTS

Runovers Continue to be a Leading Cause of Death on Canadian Farms

According to Canadian Agriculture Injury Reporting (CAIR), runovers continue to be a leading cause of death on Canadian farms, with June through August seeing the most fatal runovers.

CAIR lists the four types of runovers as being bystander runover, extra rider runover, operator runover and unmanned runover. We will look at each of these and the ways we can prevent them from happening on our farms.

Bystander runover: This is where a person is pinned or struck by a manned machine, or by a machine or implement towed by it. It can also include being run over while attempting to get on or off from a moving machine that has an operator.

- Perform a walk around of the equipment before getting on and starting it.

- Visually inspect the area around the equipment before moving it.

- Drive slowly in areas where others are present.

- Train everyone in how to get the attention of the operator and safely approach equipment (this includes not approaching it until they have been recognized by the operator and the equipment has come to a complete stop).

- Ensure children are supervised and kept out of work areas.

Extra rider runover: This is when someone who is a passenger falls from a machine and is then run over, pinned or struck by that machine, by another machine or by an implement towed by a machine.

- Extra riders should only be permitted on a tractor with an enclosed cab and with a factory-installed extra seat. This seat should only be used on a temporary basis and for instructional purposes only (i.e., when training someone).

- Do not allow extra riders; this is especially important when there is no extra seat, as someone sitting or standing in another area may lose their grip or balance and be thrown off the equipment.

Operator runover: This occurs when a person falls from a machine they are operating and is then runover, pinned or struck by it, by another machine or implement towed by a machine.

- Never attempt to get on or off a machine while it is moving.

- For tractors equipped with a Roll Over Protective Structure (ROPS) and seatbelt, always use the seatbelt!

- Before getting off of a tractor or other machine, place it in park, set the brake and shut it off.

- Ensure that the brakes and clutch are in good working order.

- Chock or block the equipment against movement; it is a quick and easy step that could save a life.

- Slow down over rough and uneven ground.

Unmanned runover: This is when a person is runover, pinned or struck by a machine that does not have an operator, or by a machine or implement towed by a machine without an operator. This includes being run over while attempting to get onto a moving, unmanned machine.

- Never start a tractor from the ground; this is often called “bypass starting.”

- Only start equipment when properly seated.

- Ensure equipment that is not in use is always turned off and placed in park with the brake set. Chock or block the tires as a quick and easy additional safety measure.

We strongly encourage you to share this information with your farm team; remember, you should never assume they know this information or have thought about it. Click on the link to download and print AgSafe Alberta’s Toolbox Talk Preventing Runovers on the Farm.

CONTACT US

For general inquiries: info@agasafeab.ca /403-219-

For our hotline for incidence assistance: 1-833-9AGSAFE